Modern technology and services have advanced a lot. No matter you are in whichever industry, the services are been taken to another level. While reading this blog, you find that the focus is on the roles of Shop drawings, Steel Fabrication, Millwork Drawing, and HVAC systems.

When there are any presentations to be given to the client, there are many ways to do it. Some of the way which has been followed is by creating sketches for product design, modeling a prototype for hands-on interaction or a visual demonstration and pitch of a product.

When it comes to creating a product, these visual representations, and concepts is not enough. A precise concept of a sketch of a building can stimulate the imagination. Here you will get the final layout of the product which will be looking real. But this cannot be used to create the components of a building to be assembled.

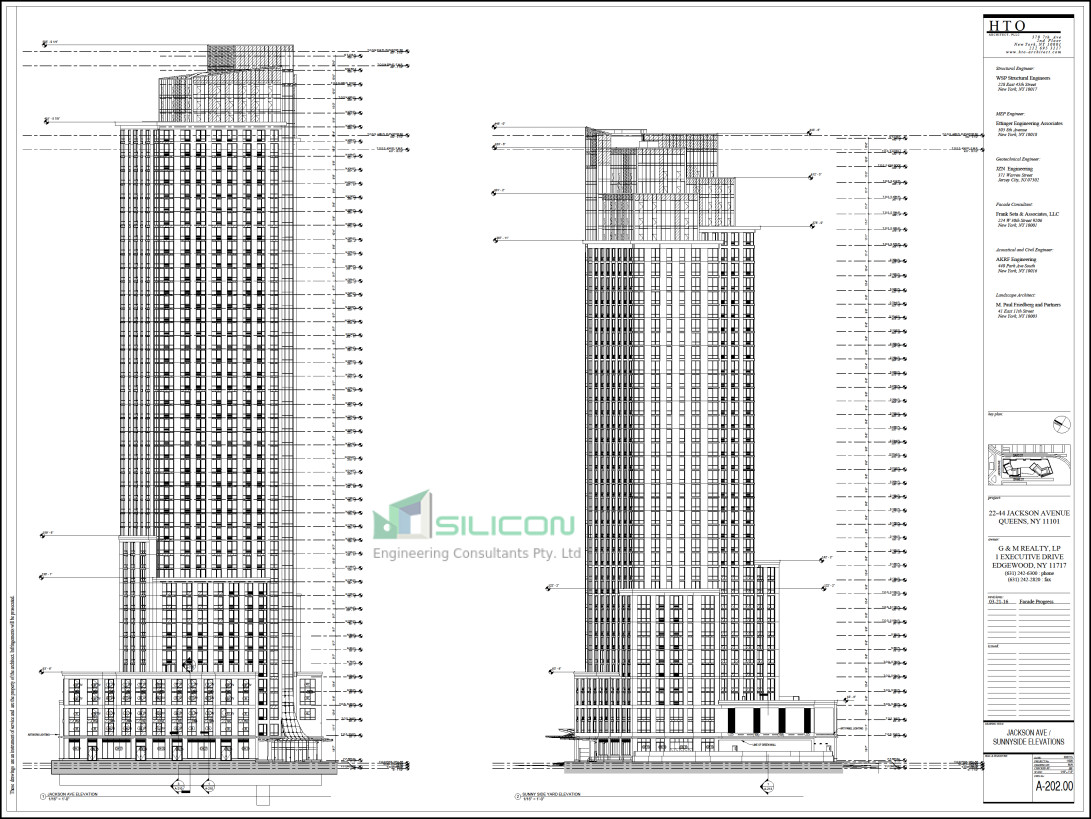

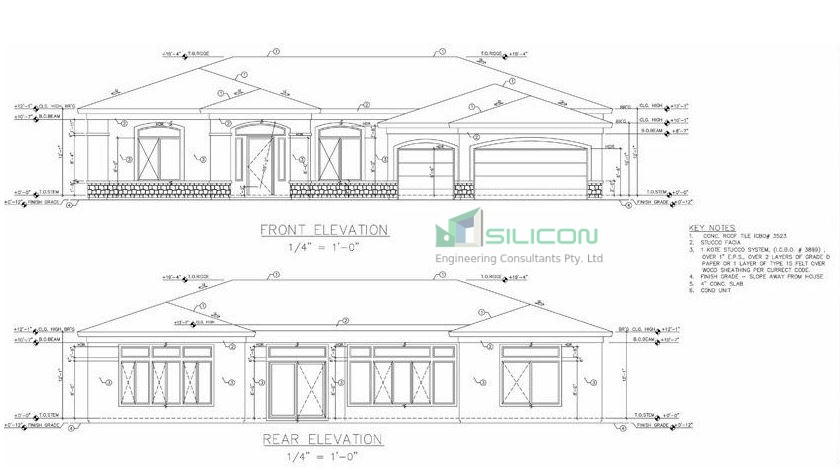

Here is where the concept of shop drawings is required. The team of specialized and trained staff is best for this service. The process of shop drawings can be followed in the form and can be assembled within controlled and calculated constraints. But have you ever thought as to how to take these images and concept sketches to the manufacturing stage? Once the client is satisfied with the design how can they move to the next stage with the initial concept drawings? All this needs to be taken care of and that is why the team of experienced is needed for their help.

The best support here we will get is from the team of shop drawings or technical drawings staff. These drawings show the information that instructs the manufacturer and make them understand. This understanding is all that the end product should look like and how it should function.

To make it more precise and clear, here the example which will give more clarity as well.

For example, a structural engineer first needs to create a steel fabrication drawings. This will be for a steel manufacturing company, to make them understand the specification of steel beams and columns need to be produced by the company. It will also need drawing for the HVAC system too. The need for this is to know the system map of how a building will be ventilated. The vehicular movement of indoor air quality along with the transmission of thermal dissipation throughout the building.

Hence, on seeing a drawing plan will always help to encourage discussion and ideas. The team of HVAC designers can use a floor plan of a building so that they can plan how air will move through it. It will also have the thought on how and where the HVAC system will be installed to ensure company standard efficiency.

The advanced and modern-day shop drawings or technical is created with the help of CAD software. Some of them are AutoCAD or Revit. The hand-drawn technical drawings are not so common these days. It is a dying art that has reduced to quick sketching for conveying ideas and concepts instantly. That is why this post will be the focus on drawings produced by using CAD drafting.

Present Design Information & Assembly Instructions Clearly.

The service which will display a scaled outline of how the final product will be assembled is "Shop Drawing." It will give all supporting information about what material is to be used, what will be the dimension of the product, the hidden components represented by dashed lines, the intended weight of the product, product-specific treatments such as 'galvanizing steel' and more.

A set of steel fabrication drawings, for example, will contain the drawings of steel components. This will give you the view from top to bottom showing specific connection details. It can also have 3D details to give a better perspective. Here, the component will have its measurement displayed which will be backed by supporting information such as Column to be primed with a protective oxide coating.

These drawings will give clarity to the fabricators to produce exactly what is required and specified for the use on the construction site.

Duplication Creation of the Same Products

Shop drawings give specific instructions and information. The process will require multiple times of designs to be created. This will also include the process of duplication of the same design and the same product every time.

The services can be useful when there is a requirement for multiple of the same components. The best example is the roof joists. It is also useful if the manufactured components are or become defective for some reason. In such a case, the exact duplicate can be rolled and formed.

If there is a contractor scheme for the development of a new house, duplications will save time and money. This is because all the houses are the same as planned and built.

Documentations

Shop drawings can be used as documentation which can be later referred to if something is amiss. For example, if a structural steel column is delivered on-site and if it seems to be tall, the designer can refer it and point the cause and time for the defect.

No matter it is the fault of the designer or the manufacturer if the design is been documented the solution to the problem can be identified soon. This will also give the pathway to determine further course of action as well.

Such documents may be compiled to seek approval. This is required by a qualified and accredited engineer. This will act as a supporting document to submit the planning authority for approval to build.

Keeping an Accounts of Components

It helps in keeping track and record of the components which are required in the construction site. If there is a large structure of the project, and you need loose parts to be assembled and delivered then it will work. As all these loose parts will be then delivered in one single piece.

Later each of these separate components will be presented in a part that needs to be organized. It can be labeled as "Part 1" and "Part 2" and so on. This can then be supported by an overall drawing which will show the final structure it is supposed to be looking. It will then later be functioned when all parts are assembled together on the site.

This can further be said for the whole building itself where each part of the building can be set in a group of drawings. Further, each set of steel fabrication drawings can be organised as per the delivery dates of the projects.

Reliable Costing

In a manufacturing business consideration of costs is a big part. And thus it should be taken into consideration carefully. Well, here is where shop drawings helps to determine the cost of the materials precisely. It is totally on the basis of the materials needed for manufacture. It helps to prevent time wastage, and overstock of the items.

They can create a plan and schedule the order in line with a current or future project to increase storage time. Usually it is seen that manufacturer will order 10% extra material then required to be at the safer side.

No doubt it may include incorrect sizes of components, and if its not possible to form it again, they can be recycled. These components can be prepared again using the extra material which is ordered.

Here the good thing about CAD software like Revit is that, its BIM tool. This means to get the exact specification and the model components fit together BIM is created in Revit. This can later be used in future to check for further components too.

The schedules further can be used to find out how much of what material is being used in the model. Along it will also have the weight of the components. This information is used to determine how much material is to order and how much it will cost.

The schedules will calculate the grand total of everything so that the figures can be used to determine the exact quotes for orders. Hence it would not be saying wrong that scheduling is a large part of the construction world.

Moving further there are some more benefits which you should consider when having the services of shop drawings. These benefits are real time corrections before the issue, portability, training, uniformity, and drawing sheet an act of promotion.

Hence, these are some of the advantages of using shop drawings. Hope it will help you and your business to get the result accurately and aptly. Apart, the costing can also be negotiated but for the same you need to get in touch with the right company or the firm who are using these technologies and are advanced with skilled knowledge.

Over to you:

No matter you are in whichever part of Australia or country if you need these services like Structural Shop Drawings Brisbane, Structural steel shop drawing services Brisbane, Facade Shop Drawing Services Adelaide, Structural steel shop drawing services Adelaide, your one stop destination is only here.

To know more about the services you can contact us or send us an email on info@siliconec.com.au or can visit our website https://www.siliconec.com.au/.

Not only this, the company has a team of experienced and skilled employees who closely work in providing ideas in many parts of Australia. So, the list of our work speciality is as mentioned here.

When there are any presentations to be given to the client, there are many ways to do it. Some of the way which has been followed is by creating sketches for product design, modeling a prototype for hands-on interaction or a visual demonstration and pitch of a product.

When it comes to creating a product, these visual representations, and concepts is not enough. A precise concept of a sketch of a building can stimulate the imagination. Here you will get the final layout of the product which will be looking real. But this cannot be used to create the components of a building to be assembled.

Here is where the concept of shop drawings is required. The team of specialized and trained staff is best for this service. The process of shop drawings can be followed in the form and can be assembled within controlled and calculated constraints. But have you ever thought as to how to take these images and concept sketches to the manufacturing stage? Once the client is satisfied with the design how can they move to the next stage with the initial concept drawings? All this needs to be taken care of and that is why the team of experienced is needed for their help.

The best support here we will get is from the team of shop drawings or technical drawings staff. These drawings show the information that instructs the manufacturer and make them understand. This understanding is all that the end product should look like and how it should function.

To make it more precise and clear, here the example which will give more clarity as well.

For example, a structural engineer first needs to create a steel fabrication drawings. This will be for a steel manufacturing company, to make them understand the specification of steel beams and columns need to be produced by the company. It will also need drawing for the HVAC system too. The need for this is to know the system map of how a building will be ventilated. The vehicular movement of indoor air quality along with the transmission of thermal dissipation throughout the building.

Hence, on seeing a drawing plan will always help to encourage discussion and ideas. The team of HVAC designers can use a floor plan of a building so that they can plan how air will move through it. It will also have the thought on how and where the HVAC system will be installed to ensure company standard efficiency.

The advanced and modern-day shop drawings or technical is created with the help of CAD software. Some of them are AutoCAD or Revit. The hand-drawn technical drawings are not so common these days. It is a dying art that has reduced to quick sketching for conveying ideas and concepts instantly. That is why this post will be the focus on drawings produced by using CAD drafting.

Present Design Information & Assembly Instructions Clearly.

The service which will display a scaled outline of how the final product will be assembled is "Shop Drawing." It will give all supporting information about what material is to be used, what will be the dimension of the product, the hidden components represented by dashed lines, the intended weight of the product, product-specific treatments such as 'galvanizing steel' and more.

A set of steel fabrication drawings, for example, will contain the drawings of steel components. This will give you the view from top to bottom showing specific connection details. It can also have 3D details to give a better perspective. Here, the component will have its measurement displayed which will be backed by supporting information such as Column to be primed with a protective oxide coating.

These drawings will give clarity to the fabricators to produce exactly what is required and specified for the use on the construction site.

Duplication Creation of the Same Products

Shop drawings give specific instructions and information. The process will require multiple times of designs to be created. This will also include the process of duplication of the same design and the same product every time.

The services can be useful when there is a requirement for multiple of the same components. The best example is the roof joists. It is also useful if the manufactured components are or become defective for some reason. In such a case, the exact duplicate can be rolled and formed.

If there is a contractor scheme for the development of a new house, duplications will save time and money. This is because all the houses are the same as planned and built.

Documentations

Shop drawings can be used as documentation which can be later referred to if something is amiss. For example, if a structural steel column is delivered on-site and if it seems to be tall, the designer can refer it and point the cause and time for the defect.

No matter it is the fault of the designer or the manufacturer if the design is been documented the solution to the problem can be identified soon. This will also give the pathway to determine further course of action as well.

Such documents may be compiled to seek approval. This is required by a qualified and accredited engineer. This will act as a supporting document to submit the planning authority for approval to build.

Keeping an Accounts of Components

It helps in keeping track and record of the components which are required in the construction site. If there is a large structure of the project, and you need loose parts to be assembled and delivered then it will work. As all these loose parts will be then delivered in one single piece.

Later each of these separate components will be presented in a part that needs to be organized. It can be labeled as "Part 1" and "Part 2" and so on. This can then be supported by an overall drawing which will show the final structure it is supposed to be looking. It will then later be functioned when all parts are assembled together on the site.

This can further be said for the whole building itself where each part of the building can be set in a group of drawings. Further, each set of steel fabrication drawings can be organised as per the delivery dates of the projects.

Reliable Costing

In a manufacturing business consideration of costs is a big part. And thus it should be taken into consideration carefully. Well, here is where shop drawings helps to determine the cost of the materials precisely. It is totally on the basis of the materials needed for manufacture. It helps to prevent time wastage, and overstock of the items.

They can create a plan and schedule the order in line with a current or future project to increase storage time. Usually it is seen that manufacturer will order 10% extra material then required to be at the safer side.

No doubt it may include incorrect sizes of components, and if its not possible to form it again, they can be recycled. These components can be prepared again using the extra material which is ordered.

Here the good thing about CAD software like Revit is that, its BIM tool. This means to get the exact specification and the model components fit together BIM is created in Revit. This can later be used in future to check for further components too.

The schedules further can be used to find out how much of what material is being used in the model. Along it will also have the weight of the components. This information is used to determine how much material is to order and how much it will cost.

The schedules will calculate the grand total of everything so that the figures can be used to determine the exact quotes for orders. Hence it would not be saying wrong that scheduling is a large part of the construction world.

Moving further there are some more benefits which you should consider when having the services of shop drawings. These benefits are real time corrections before the issue, portability, training, uniformity, and drawing sheet an act of promotion.

Hence, these are some of the advantages of using shop drawings. Hope it will help you and your business to get the result accurately and aptly. Apart, the costing can also be negotiated but for the same you need to get in touch with the right company or the firm who are using these technologies and are advanced with skilled knowledge.

Over to you:

No matter you are in whichever part of Australia or country if you need these services like Structural Shop Drawings Brisbane, Structural steel shop drawing services Brisbane, Facade Shop Drawing Services Adelaide, Structural steel shop drawing services Adelaide, your one stop destination is only here.

To know more about the services you can contact us or send us an email on info@siliconec.com.au or can visit our website https://www.siliconec.com.au/.

Not only this, the company has a team of experienced and skilled employees who closely work in providing ideas in many parts of Australia. So, the list of our work speciality is as mentioned here.

No comments:

Post a Comment